Hello! I’m Alex

I am currently working on AGI preparedness, by building AI decision making tools for governments and institutions and to prepare for an accelerated world. See what I am currently doing here.

I created NLP pipelines on materials data when I was at MIT, used active learning to design better materials at Citrine Informatics, applied reinforcement learning to solve industrial control problems at Microsoft Bonsai. And build the first wave of Copilots as a Product Manager at Microsoft Fabric - Microsoft’s new data platform.

I think to apply AI in a thoughtful and deliberate way, we need more people who can work and communicate across domains. I tried to get a broad education, and have degrees in:

- MS Technology & Policy - MIT

- MS Computer Science - MIT

- MEng Advanced Manufacturing & Design - MIT

- BEng Mechanical Engineering - University of Edinburgh

I am a global citizen - I grew up moving every 2-4 years, and have lived in the Netherlands 🇳🇱, Singapore 🇸🇬, Indonesia 🇮🇩, the Bahamas 🇧🇸, France 🇫🇷, Scotland 🏴, and the USA 🇺🇸. Always looking to connect with fellow Third Culture Kids! Reach out if you happen to stumble across me.

What I did

Copilots for data science

At Microsoft Fabric I was a Product Manager on the founding team of the copilots initiative. We imbued the new flagship data platform with AI capabilities. Imagine writing things like “please analyze this dataset for anomalies” and actually getting timesaving and trustworthy results. We shipped one of the first text-to-SQL engines, LLM data scientist, and a few other things.

You can see some of these features here.

Reinforcement Learning for Industrial Control

2021-2023

At Microsoft Bonsai I helped companies implement Reinforcement Learning (RL) solutions to solve hairy control problems.

The basic approach was: Step 1: build a simulation. Step 2: train an algorithm to control that simulation. Step 3: deploy the trained algorithm on real hardware. Turns out that every one of those 3 steps is pretty hard and I worked across the entire problem space.

I first did this work as a client-facing AI Engineer, and later I switched over to Product Management, where I in charge of the core AI algorithms and capabilities. The features were shipped were learning directly from data (“Offline Reinforcement Learning”), increasing robustness in the face of imperfect simulations, and accelerating training speeds.

Microsoft decided to discontinue this product, but I continue to believe in the approach.

Active Learning and Materials Informatics

2019-2021

At Citrine Informatics I helped top materials companies create better materials using machine learning. I started as data scientist and eventually worked as a tech lead, where I got to work with a team of data scientists and engineers.

We used bayesian optimization (in essence; find the most valuable experiments to run every iteration) with some special materials featurizations. Using this technique we helped various companies achieve breakthrough insights in different systems, ranging from glass, to metals, to polymers.

Beyond the technical execution of specific projects I helped companies develop their AI strategies; working with executives to create a vision, setting up data collection practises, and training their researchers in data-driven exploration.

I can’t talk much about specific work I did, because most of it was highly secretive (I know.. very mysterious!), but I worked on these two project:

- Case study: Rapid Polymer Screening using AI

- Case study: Glass Development - Machine Learning Accelerates Research

And I was a co-inventor on a patent: Product design and materials development integration using a machine learning generated capability map

Automatic Information Extraction from Materials Science Journal Articles

2016-2019

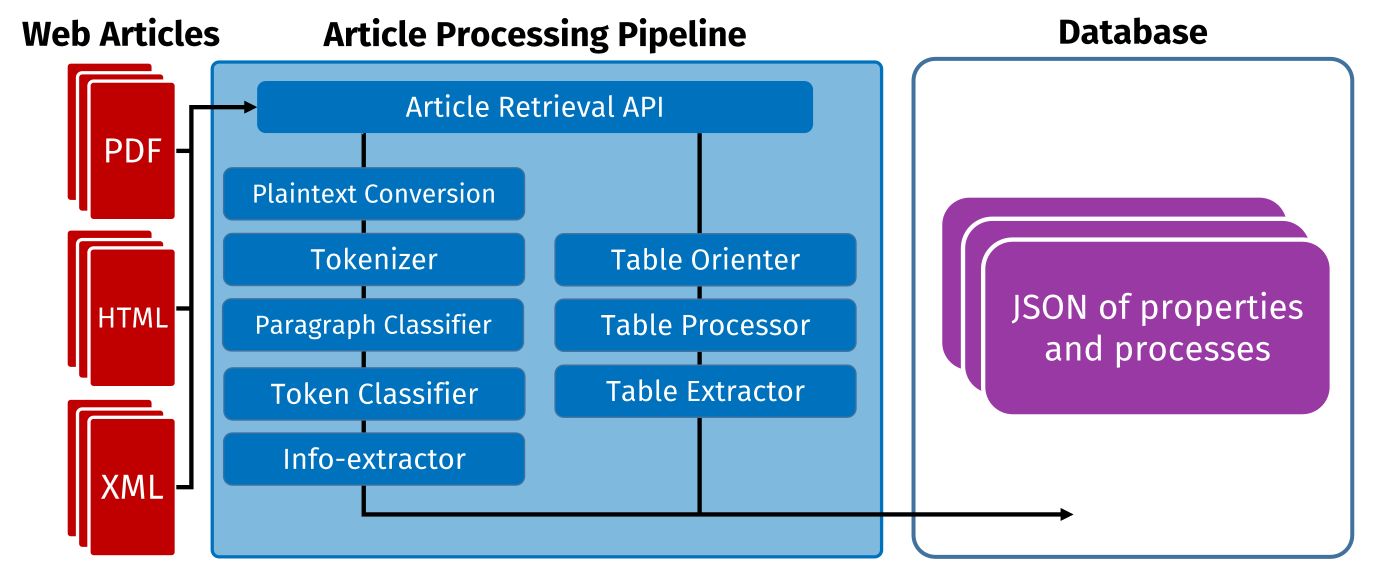

In the Olivetti Group at MIT we built systems to automatically extract information contained in materials science papers (the input ingredients, the process, the resulting properties). Once you have that dataset, there is a lot you can do like creating comprehensive maps of what has/hasn’t been tried to give other researchers new ideas, or automatically generate new synthesis paths for materials.

The technology has come a long way since then. We were using Word2Vec (in later pipelines; BERT), created our own LSTM-based Named Entity Recognition systems trained on painstakingly labeled data, built table parsers, and more.

You can read about this here:

- Inorganic Materials Synthesis Planning with Literature-Trained Neural Networks

- Manufacturing variability; effects and characterization through text-mining.